Gear Testing, News, Phase One

The Phase One XF Story – Past, Present & Future

How Long-Term Thinking at a Small Danish Company Has

Reinvented Medium Format Again and Again

Prologue

Team Phase One makes raw workflow software, digital backs, camera bodies, and lenses. Three of these have received major overhauls in recent years. Capture One was rewritten from scratch in 2008, leading to what has become the best raw workflow software in the industry. In 2011, Phase One replaced its venerable P+ series with the revolutionary IQ series . With their strategic partner Schneider Kreuznach, Phase One released lens after lens, resulting in a fully modern line of leaf shutter and focal plane lenses. All the while the photo world has waited for a ground-up redesign of their 645 body.

The photo world waits no longer. The Phase One XF Camera System has arrived.

If this is the first you’ve heard of the Phase One XF, I’d suggest first reading Phase One XF First Look and The New Phase One XF Camera System. This article will not cover the specifications; it is not a tour of features. Instead, it puts the XF in the broader context of Phase One’s research and development strategy – past, present, and future.

To understand Phase One’s fourth, and most significant overhaul, it’s important to review the three previous overhauls: software, digital backs, and lenses. With these historical efforts we have the benefit of hindsight to see how they illustrate the long-term thinking that dominates R+D at Team Phase One. The XF represents the culmination of a decade of work to move beyond just making components, to making a unified camera system.

The Past

Raw Software Reboot

In 2006, Capture One Pro v3.7 was still class leading. It had the fastest raw processing, best color engine, most robust tethering, and a strong user base. But Capture One Pro v3 was built on a foundational platform first developed in the late 1990s, and it was showing cracks in its foundation.

Phase One could have continued updating the Capture One Pro v3 platform, adding new features and chasing bugs, and it would continue to sell well for several more years. A company with short-term vision, might have done this. After all, it goes against most traditional business strategies to make a huge investment to entirely replace the foundation of one of your flagship products, especially when sales of that product have never been better.

Instead, they increased their software R+D team, nearly doubling its size, so that they could build a brand new foundation for Capture One while keeping the v3 platform up to date. The multi-year project to build an entirely new foundation for Capture One debuted in 2008; every new version of Capture One since then has been built on that foundation.

Digital Back; Replacing a Giant

In 2008, the Phase One P 65+ was the most successful digital back Phase One had ever released. It was the first full-frame 60mp digital back. It had an ISO range that extended up to 3200, unheard of in medium format at the time, and was the fastest high-res system on the market. It was the pinnacle achievement of a P Platform of digital back first released in 2004. The P 65+ was a technical achievement, pushing the P to its foundational limits. But, like Capture One Pro v3, development was hitting a wall. The platform itself was aging, and growing new features and products on top of it was becoming increasingly challenging. For example, the first P back could capture around fifty 16mp raw files per minute, and extensive tweaking was required to reach sixty 60mp raw files per minute for the P 65+ (nearly 5 times faster data throughput).

Perhaps if the P 65+ were less successful Phase One would have been forced to stick with the aging P Platform, perhaps releasing a P 80+. Later they could even release a CMOS P 50+ based on their legacy platform; it would have had laggy low-res live view and slower continuous shooting rather than the fully realized IQ250. For an alternative history, one only needs to look at the other medium format digital back companies who lacked a P 65+ to help them financially weather the storm of the great recession.

The enormous success of the P 65+ provided Phase One profits during the recession, when others were struggling just to stay solvent. Phase One CEO Henrik Håkonsson channeled these profits into long-term investments, and one of the earliest rewards of that investment came in 2011 with the release of the Phase One IQ platform. We said at the time that the IQ was 3-4 years ahead of its time, and now nearly 5 years later it seems this may have been conservative; its touch screen interface, retina LCD, review capabilities (focus mask, adjustable exposure warning), and software integration (auto horizon correction, auto perspective correction, USB3 and Firewire 800) are still unmatched.

The IQ project was meant to provide not just a stellar product, but a platform on which Phase One could build for years to come. The IQ2’s introduction of built-in wifi review/editing/control and the IQ3’s new features such as the clipping warning based on the true raw file and heat-map style zone exposure system show the promise of an extensible platform has been fulfilled.

Schneider, Leaf Shutters & Lenses: Ready for Tomorrow

When the Mamiya 645 was competing with the Pentax 645 and others for film shooters, lenses were only asked to resolve around 30-40 megapixels worth of subject detail for the full 645 frame. When the Phase One P 45 (near full-frame 39mp digital back) was released in 2005 it became clear that Phase One would need new lenses as it pushed forward with higher resolution digital backs. A year later, in 2006, Phase One announced a strategic investment in Mamiya and in 2009 they extended that investment into a controlling interest. Phase One was now in the driver’s seat and began pouring money into lens development. This included starting an alliance with Schneider Kreuznach, which has become one of the most fruitful collaborations in the world of photographic optics.

Unlike backs, bodies, or software, the revamping of a lens lineup requires lots of medium projects rather than one large project. Every year since 2009 the line of Team Phase One new modern digital lenses grew, often going largely unnoticed by the public. With the release this week of the 35LS and 120LS that lineup now includes a staggering 19 modern digital lenses including 10 with leaf shutters, most of which sync at 1/1600th of a second. This is, by far, the most complete line of modern design lenses in medium format.

Bringing a single new lens to market is a multi-year effort. At the time Phase One began this process Mamiya lenses were still sufficient. The P 45 was only beginning to hint at the weakness in the legacy film-era lenses which wouldn’t become fully manifest until later higher resolution backs were released. Instead of waiting for lenses to become a limiting factor Phase One surged investment into their lens lineup. The result is the strongest line of lenses available in medium format, capable of handling full-frame resolutions exceeding 100mp.

Reaping Its Rewards

Phase One heavily invested in R+D to entirely replace its flagship software, backs, and lenses. It did so at a time when each was still very profitable, and in the case of the P+ digital back and Capture One software, still industry leading.

The market has rewarded them handily. Revenue in 2014 was nearly double that of 2009. Their backs, raw software, and lenses are widely considered the best in the industry. In short, the investment paid off both for Phase One and its users.

The Present

Waiting for the Car to Warm Up on a Cold Morning

There is a great divide between the experience of an R+D team working on a project and the customers waiting for the fruit of their labor. This is especially true of multi-year projects. In the past few years some observers concluded that Phase One had its collective head in the sand and was content to continue with incremental improvements to its 645 platform. Nothing could be further from the truth; investment in a ground-up modern Phase One body began as early as 2009.

The timeline to develop a brand new platform is both lengthy and inherently uncertain. You cannot know how long it will take. In any large R+D project some of the components are easier and faster to complete than expected, while others take much longer and are more complex than predicted. In the interim, Phase One wanted to provide existing customers a better experience. Accordingly, two separate R+D programs ran alongside each other: one to improve the existing Mamiya 645 platform (resulting in the Phase One DF and DF+ bodies) and another to develop a new platform from the ground up (resulting in the Phase One XF). This strategy enabled Phase One to provide improvements for existing customers, and also gave them ample time to ensure the second project could be done well.

“The hardest challenge as a CEO of a technology company is to balance investing in the present and investing in the future. The greater the investment in the future you make, the more ambitious you make your long-term product pipeline, the longer it takes to come to market. With the Phase One DF and DF+ we invested in our present platform. But all the while we were making massive investments into developing the XF platform. We know that by making a larger investment and taking our time to do this platform right we have frustrated some of our customers. But I know it was the right decision, and now we can finally share the results of that investment.”

– Henrik Håkonsson, Phase One CEO

The clean and modern interface of the Phase One XF shown next to the traditional interface of the Phase One DF+. The combined use of touch screen, hard buttons, and three dials coupled with a high-res LCD opens up entirely new user interface possibilities

The Tyranny of Tabula Rasa

The hardest, and most important phase in any R+D project is the very beginning: establishing the goals and core values of the project. Starting from a blank sheet of paper simultaneously offers unlimited freedom and many potential pitfalls. With the Phase One XF body much soul searching was done early on, through a combination of freeform R+D meetings and discussions with customers, and in true Danish form, debates held in dimly lit bars late at night.

In short, Phase One had to decide “what is a camera body” – a question which is as complicated as it is simple. Early discussions included some truly wild ideas but in discussions with customers it was found, again and again, that whiz-bang features and esoteric designs were simply absent from customers’ wishlists.

“We did not design the XF to fulfill a set of features we could check off on a list of marketing bullet points. We designed it to be a platform, that would enable us to continue to invent and implement new ideas now and into the future.”

– Lau Nørgaard, Phase One Technical Project Manager

From these formal and informal brainstorming sessions a few core values emerged. These represent what Phase One’s R+D team feels a body should be:

- Simple and Intuitive: A great body is nearly invisible. While in use the less the photographer thinks about the body, the more they can focus on the subject/lighting/moment and other elements of their craft. Basic operations should not require more than one dial or button, and should not require removing your eye from the viewfinder.

- Customizable: Phase One has always recoiled from the idea that one size fits all. There are dozens of unique use cases for a camera body; a portrait shooter and still life shooter have little in common.

- Reliable: Pros are under enormous stress to deliver and enthusiasts are spending their hard-earned free time. A body should simply work – every time.

- Problem Solving: Features should not be thrown in for marketing or to match a competitor just for the sake of matching them. Every feature should solve a problem that customers actually face.

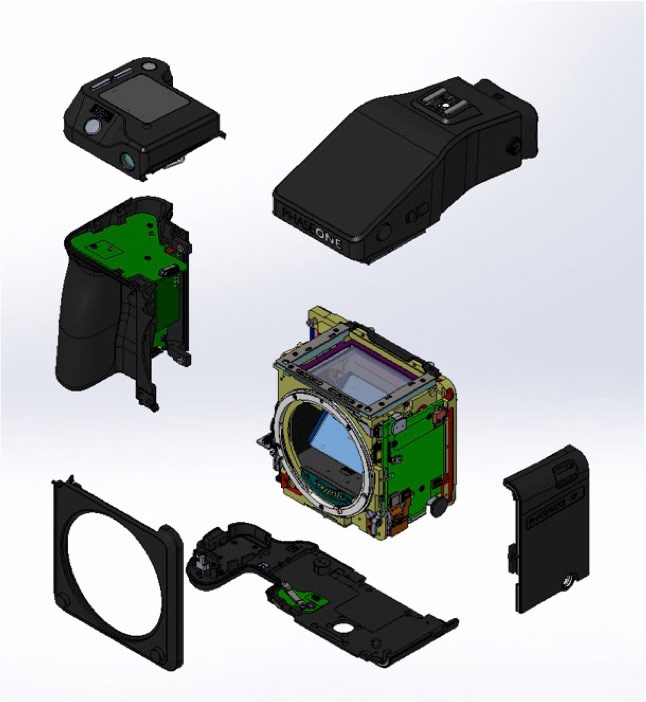

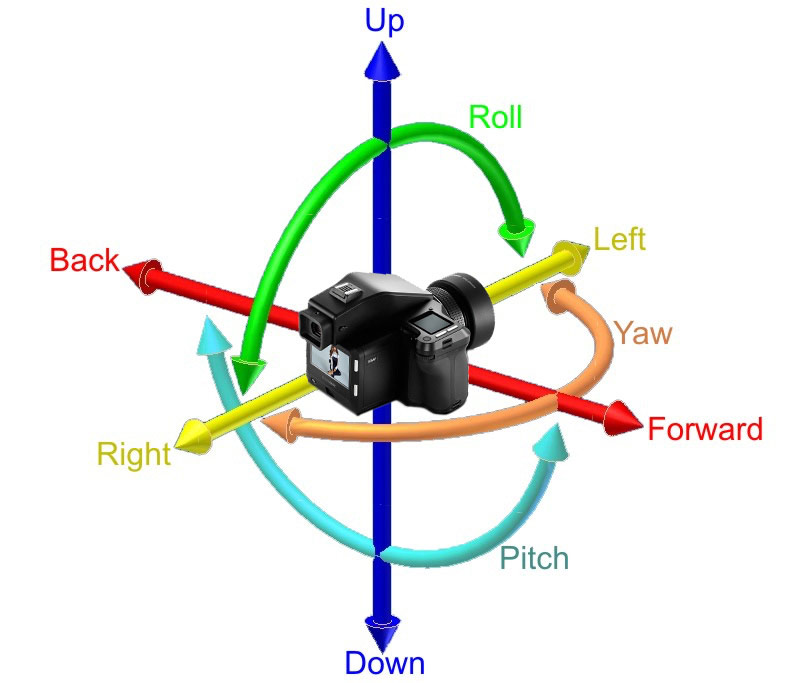

There was one more core value specific to the Phase One approach: ready for the future. In an open, modular system the body acts as a communication hub. It serves as a nexus for the back, lenses, accessories (e.g. viewfinder), and flash. Whatever Phase One wanted to do with any component of their system in the coming years the body needed to be ready to facilitate. Thus the body needed Fast Internal Architecture and custom-made field programmable CPUs that could handle not only the computation for today’s features, but whatever Phase One dreams up in the coming years.

“The top achievement of a great camera body is not to impress you with features, but to get out of your way. A body should impress you with its responsiveness and ergonomics, not with gimmicks and buttons. Once customized to your shooting needs, the best body simply disappears, becoming an extension of your eye and will.”

– Niels Knudsen, Phase One Image Professor

Going Systematic While Remaining Open Platform

The XF represents a sea change for Team Phase One. The team working on body development and the team working on digital backs have worked closely together for years. But with the XF project the distinction between the two was dropped entirely. There is now one team dedicated to creating a Camera System (back + body). Moreover, the camera system team worked with the software team during every stage of R+D so that the three elements would not just talk together – they would sing. You can see the result of this reorganization by looking at the list of tightly-integrated features. For instance, the camera interface can be accessed from the digital back (IQ2 or IQ3 only) or from Capture One; the same layout of tools, capabilities, and options are available in all three. At a very fundamental level the three systems (XF, IQ, and Capture One) are no longer tightly coordinating; they are functioning as one system.

Support for third parties continues unabated. The newly released IQ3 80mp for instance is available and compatible with the H1, H2, H4X, H5X and all Hasselblad 500 bodies. Team Phase One, in fact, is the only company that provides digital backs to Hasselblad customers with features like native USB3, retina resolution touch screens, 80 megapixels, and long exposure in a 60+ megapixel sensor.

But the Hasselblad H body uses a legacy digital interface which has not been significantly improved since its release in the early 2000s. Many of the features Phase One is working on for the IQ platform (both for firmware updates to the current backs and for whatever comes in the future) require a more modern interface. So while support will continue for third party bodies (“open platform” is in Phase One’s blood) there will certainly be advantages for those using the Phase One XF System.

The Nerdy Particulars

Some readers might be interested in some of the particulars of the XF systems development. Others may wish to skip down to the next section about the future.

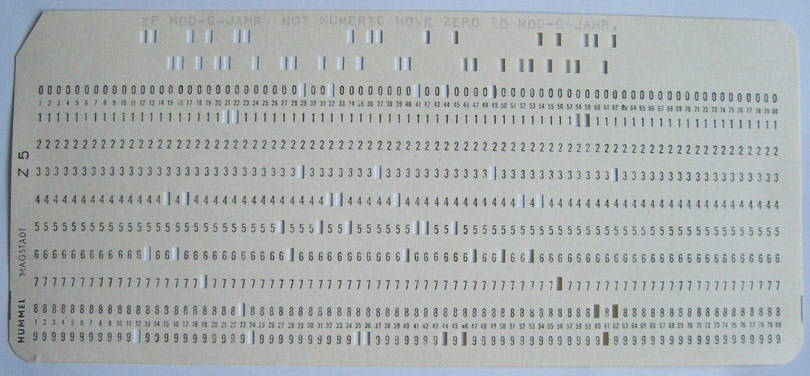

The Mamiya AFD was released in 2001 and provided a cutting edge digital interface called the Mamiya Serial Bus (MSB). This interface, like all camera interfaces, provide the foundation for both internal and external communication. Internally the interface controls mechanical elements such as the mirror and shutter, coordinating hundreds of physical steps in precise order and rhythm for every capture. Externally the interface communicates with the lens, any accessories such as the vertical grip, as well as the digital back. For example, it will ask the digital back if it has any storage left or what ISO it is set at.

My mother, now in her waning years, was a programmer in the early days of computing. She learned COBOL, an early programming that came into widespread use in the 1960s, and was used extensively in myriad large-scale business applications like the telecommunications billing management system she ran for a decade. Doing work in COBOL was arduous, error-prone, and time consuming. You could create amazingly complicated and powerful programs using COBOL, but making a seemingly minor change to that program might cause a major bug somewhere else in a seemingly unrelated area of the program. Modern programming languages, and the new approaches to programming they allow, are far faster, nimble, and extensible. What once took a team a week now takes a single programmer an afternoon. What once required complete rewrites now requires only a few minor changes.

The operating system and interface of the Mamiya 645 AFD was not written in COBOL, but the descriptions above are a pretty good fit for what it was like to work on features or bug fixes for the Mamiya 645 based bodies. For example, Phase One wanted to coordinate the power-on of the body with the power-on of the back, so that turning on the body would turn on the back as well. While this seems like an arbitrarily easy task, it took the team nearly one year to implement this feature and get it working in all situations.

In comparison, during the development of the XF, Allison Watson of Digital Transitions spent an afternoon in Copenhagen playing with a prototype, and made a few suggestions that were implemented by the next morning when she returned for a second session. This ability to rapidly implement features and changes is the result of a new operating system and new Phase One Inter Processor (PIP) communication protocol.

“The new PIP Protocol in the Phase One XF is used for all communication between [Back and Body] and [Body and Viewfinder]; it is designed to integrate smoothly into the IQ WiFi implementation and the protocol used for tethering via USB. The operating system used is a familial extension of the Phase One IQ operating system, adapted to the different roles and conditions present in the body and viewfinder.

The combination of the new Camera Body OS, PIP protocol, and numerous built-in sensors gives the new camera the possibility to continuously monitor its state of health and do many new kinds of status, error and diagnostics reporting and logging. Modern tools and compilers and one team are now responsible for the development across body, back and viewfinder and working closely with Capture One as well as Capture Pilot developers allows us to focus on creating system-coordinated features.”

– Lau Nørgaard, Phase One Technical Project Manager

In addition to a new firmware and communication protocol and new mechanical components the Phase One XF also contains new and vastly more powerful electronics, opening up whole new worlds of functionality. For instance, in a dSLR camera with a traditional autofocus system, a pair of line sensors is used, like in the Canon 1Dx, which has data from a few dozen points to correlate. The new HoneyBee autofocus platform found in the Phase One XF, has around one million light sensitive points from a single fast refreshing 2D sensor. The HoneyBee system uses a dedicated autofocus processor, developed by Phase One, to handle the image data. This CPU is, in its nature, field programmable, able to handle the large stream of data, and find the best correlation, and drive the focus the camera. It is a solution unique to the Phase One XF system and provides, by far, the fastest and most accurate autofocus in medium format.

“As the resolution of image sensors grow, and the performance of the lenses gets better and better, the demands for perfect focus precision increases with it. Focusing is a more and more essential part of a modern camera, and the bar keeps rising for what precision is needed.

Take decades of experience within digital imaging, photographic understanding, image processing, modern high speed hardware design, optical knowledge, programmable logic, precision motor control. Concentrate that in a small dedicated group of people determined to push the limits of medium format precision. The result? A radically new type of autofocus ready for these modern challenges.

Every modern dSLR camera uses phase detection of line pairs for its autofocus engine. In the past we have been as guilty as everyone else of assuming that the ubiquity of this approach implied superiority. But when we started work on the Phase One XF we knew we wanted more than the standard incremental improvements. We began experimenting with using a dedicated super-fast CMOS sensor, and image processing through CPU control.

Rather than relying on a few dozen specifically oriented lines in a phase detection system, we could gather data from millions of pixels, correlating pieces of textures, shapes, and curves which confound traditional line detectors. Moreover we can completely reconfigure the response of the autofocus using firmware rather than be limited to the specific geometry etched on a traditional line sensor. We have provided a robust first implementation of the autofocus system, with a slew of new and even better implementations by enhancing the software of our Honeybee autofocus platform over time; it is already far more precise than any medium format autofocus system available.”

– Thomas Andersen, Phase One Chief Technology Officer

The Future

Built to Last

Other companies have incrementally replaced their bodies, obsoleting the previous generation just to add simple features. Most companies give their bodies just enough processing power and only include hardware components which they are ready to make full use of. Phase One itself was guilty of this with the DF+ and DF bodies. And, to be realistic, photography will never again return to the era when a camera body would last a photographer 30 years. But Phase One has made every effort to make the XF a lasting platform, capable of extensive upgrades in the field via firmware, and capable of accepting new/upgraded digital backs for years to come.

Picking the brain of the R+D team at Phase One is both terribly exciting and terribly frustrating. Exciting because they have so many good ideas of how to use all the power and components they’ve fit into the XF. Not silly gimmicks, but useful tools that would solve problems photographers face every day. Frustrating because when you hear some of the ideas you can’t help but want them RIGHT NOW, and even more frustrating because, as a matter of policy they cannot be shared.

“Now that we have a stable and modern platform for the entire system, there are so many cool things we can make and so many interesting places we can go with this system.”

– Lau Nørgaard, Phase One Technical Project Manager

Nothing Up My Sleeve

Some of the XF’s internal components, like the high-precision 6-Axis Gyroscope and Accelerometer are only used in a very basic way at the moment (i.e. in the Seismograph mode); they have great ideas of how they might use that component, some of which you might guess and some of which you’d never dream of. Other components aren’t even turned on in the firmware and will remain secret until they are turned on, or until some brave soul takes their body apart piece by peice.

It should be noted that a careful inspection of the lens mount reveals that there are more communication pins than are used on current lenses.

The XF was born the most advanced medium format camera body available. It offers class leading autofocus, tight integration with the digital back and software, and powerful tools like the Seismograph. With future firmware updates it will push even further ahead of the competition and offer photographers unique and powerful tools that will solve the problems they face every day.

Continued Investment Makes for a Bright Future

Reading forums and blogs you might think medium format has died a dozen deaths over the years. Every new camera, it seems, is the “death knell” for high-end cameras. Yet Phase One’s revenue and investment in R+D continue to grow. These are not unrelated phenomenon. Under the continuous direction of its founders it has focused on serving the world’s best photographers, developing tools that help them stand out from an increasingly crowded and homogenous field of okay photographers.

In the present the Phase One XF Camera System and Phase One IQ3 digital backs offer a complete camera system years ahead of the competition. In the past Phase One has continued to invest aggressively in long-term projects rather than resting on the laurels of successful products, by investing in replacements for products while they are still selling well. That points to a bright future for Phase One customers, and a bright future for Phase One itself. Phase One isn’t done; in many ways it is just getting started.